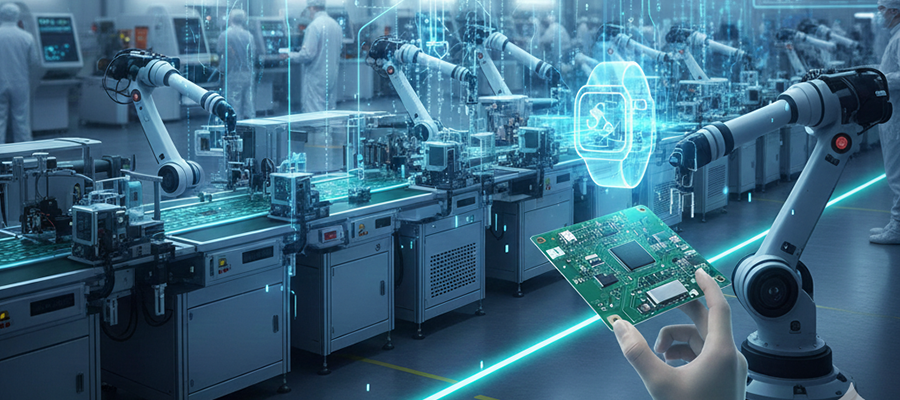

Industry 4.0 – Connected Manufacturing

We are leveraging Industry 4.0 technologies for smart factories, including IoT for real-time monitoring, cloud computing for data storage and process standardization, and robotics for automated PCB assembly and supply chain management. These enable seamless machine connectivity, predictive maintenance, and enhanced efficiency in producing consumer electronics and connected devices. This setup boosts accuracy, reduces downtime, and supports mass production of smart products.

Industry 5.0 – Human + AI Collaboration

We are transitioning to Industry 5.0 by integrating human creativity with AI, machine learning, and advanced CNC technologies for human-centric, sustainable manufacturing. Future plans include flexible supply chains for mass customization, real-time data analytics, and workforce upskilling to combine human skills with automation. This shift emphasizes resilience, net-zero emissions, and responsive operations to meet evolving market demands