Manufacturing Infrastructure

- All

- Surface Mount Technology (SMT)

- Through-Hole Technologies

- Testing & Validation

- Protective Processes

- PCB Routing & De-Paneling

- Box Build Systems

Clean Rooms

Controlled environments for high-reliability builds

- ISO 6 Cleanroom: Dedicated SMT line

- ISO 8 Cleanroom: Box build & testing

- 24×7 temperature & humidity control

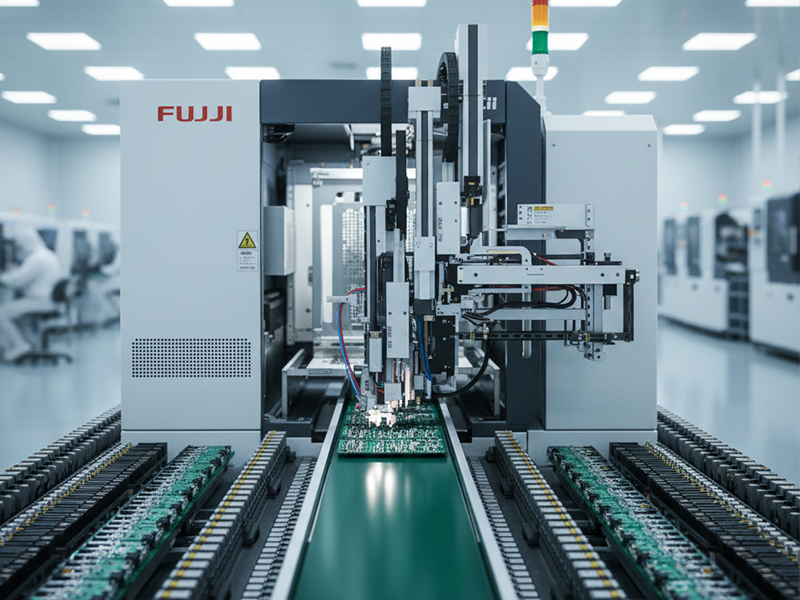

Surface Mount Technology (SMT)

Fuji GPX-CII Printer

- 6-sec cycle time

- 10 μm @ 6 sigma alignment accuracy

Surface Mount Technology (SMT)

Fuji NXT-R Mounter

- ±25 μm placement accuracy

- Smart feeder traceability

- Modular, high-speed configuration

Surface Mount Technology (SMT)

JT Reflow Oven

- 15% improved heat transfer efficiency

- Long heating zone for higher throughput

- Nitrogen chamber with O₂ as low as 150 ppm

Surface Mount Technology (SMT)

Koh Young 3D AOI

- 15 μm resolution

- Height + shape + surface inspection

- SPC-driven process improvement

Through-Hole Technologies

Wave Soldering – JT

- Controlled fluxing, preheat & wave height

- Stable solder pot with dross management

Through-Hole Technologies

Selective Soldering – Kurtz

- Programmable nozzle path

- N₂ atmosphere + top/bottom preheating

- Parallel soldering of 4 PCBAs

Testing & Validation

Takaya Flying Probe

- Fixture-less ICT

- Ideal for NPI/low volume

- Detects opens, shorts, polarity, orientation

Testing & Validation

iTest ICT

- High-speed, high-coverage electrical testing

- Detailed reporting for mass production

Testing & Validation

Functional Testing

- Real operating conditions & I/O simulation

- Firmware, interface & performance checks

Protective Processes

Conformal Coating – ANDA

- Selective spray with controlled thickness

- UV/thermal curing

- Protected zones for connectors & no-coat areas

Protective Processes

Potting (1K/2K)

- Controlled mixing, dosing & degassing

- Bubble-free, consistent fill

- Enhanced insulation & durability

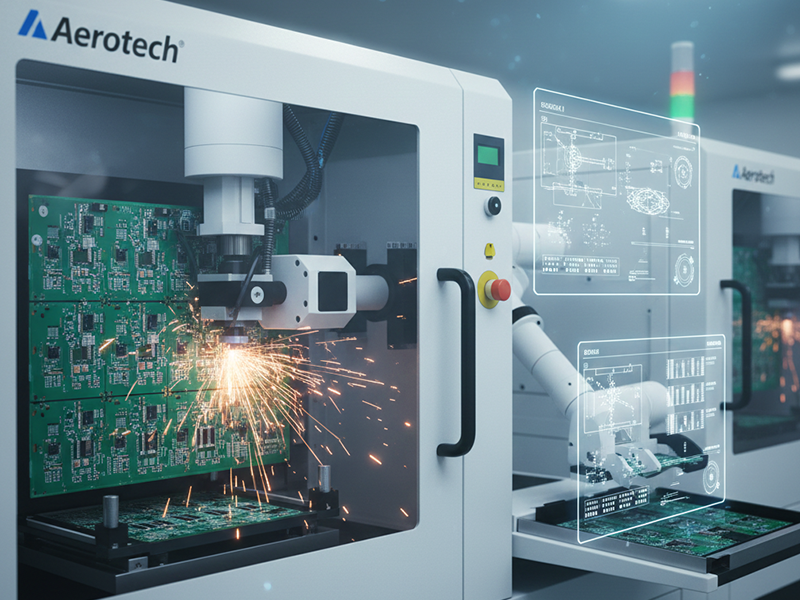

PCB Routing & De-Paneling

Aerotech Router

- Router/V-cut/laser processes

- Low-stress PCB separation

- ±0.08 mm cutting precision

Box Build Systems

Expertise in EV & Industrial Electronics

- BMS, BCU, DTU, OBC, VIC

- High-voltage-ready stations with safety interlocks

- Automated screwdriving, gluing & potting

- Recipe-driven cells for variant builds

- MES-enabled zero-paper governance

- Full traceability + poka-yoke + in-line QC

Box Build Systems

Assembly Capabilities

- Harness routing, busbar integration

- Gap fillers, pads & heat sink installation

- Sealing: gaskets, gluing, potting

- Firmware flashing & calibration

- CAN/LIN/RF validation

- ICT/FCT/EOL with torque & vision data logging